Role of Plant Maintenance in Production Management.

Plant maintenance is defined as a set of activities that are necessary to keep machinery, parts & types of equipment in good operating conditions to avoid production stoppage and loss.

Objectives of maintenance management.

- Minimizing the loss of production time due to equipment failure

- To reduce loss due to the production stoppage.

- To keep all productive assets in good working conditions

- Improve the quality of the product and improve productivity

- Helps to reduce the total maintenance cost of repair, preventive maintenance & inventory carrying a cost due to a spare part inventory.

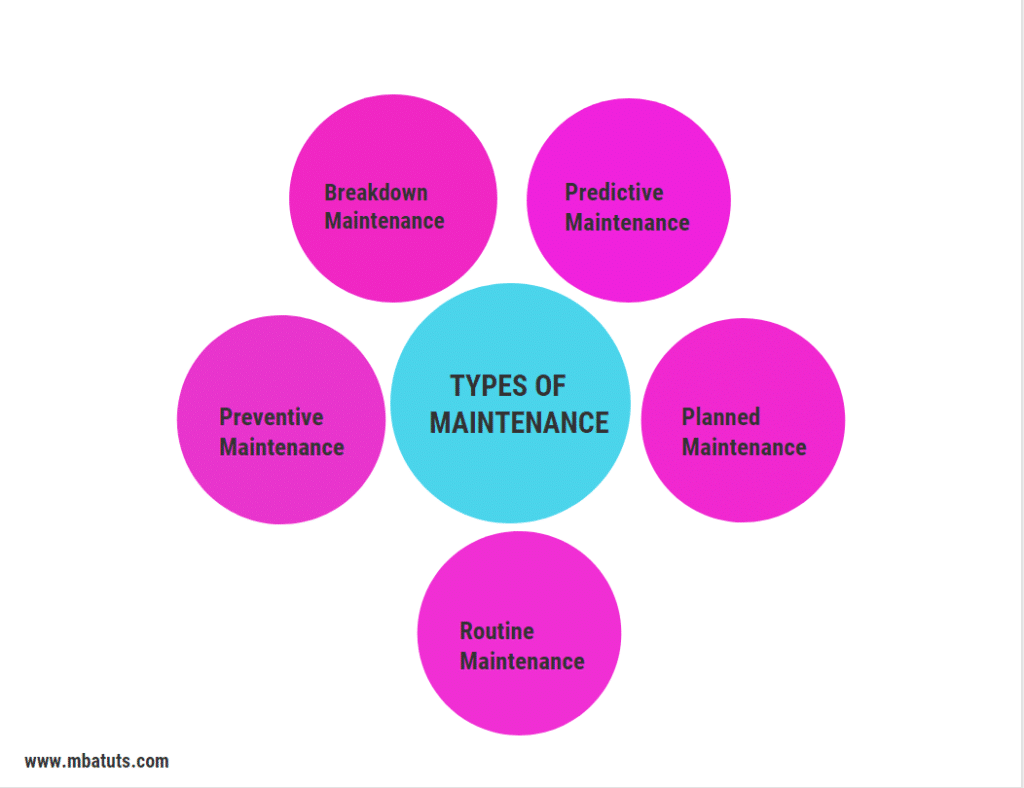

The following are different types of maintenance.

1. Breakdown Maintenance

This is also called corrective maintenance it occurs when work gets stopped because of a machine breakdown. In this sense, maintenance becomes repair work. Repairs are made after the equipment is out of order

For eg- A electric motor will not start if the conveyor belt is ripped or the shaft has broken. In this case, the maintenance department checks into difficulty and makes the necessary repairs

2. Preventive Maintenance

In contrast to corrective maintenance, preventive maintenance is undertaken before the need arises and aims to minimize the possibility of un-anticipated production interruptions or a major breakdown, preventive maintenance consists of,

a) Proper design and installation of equipment.

b) periodic inspection of plant & equipment.

c) Repetitive servicing of types of machinery.

d)Adequate lubrication, cleaning, and painting of the building.

3. Predictive Maintenance

One of the new types of maintenance that may be anticipated to gain increasing attention. In this sensitive instrument is used to predict trouble conditions that can be measured on a continuous basis and this enables the maintenance of people to plan for an overhaul.

4. Routine Maintenance

This includes activities such as periodic inspection cleaning, lubrication& repair of production equipment. This can be classified into two types,

i) Running maintenance

In this, the maintenance work is carried out while the equipment is in operating condition.

ii) Shutdown maintenance

Here the maintenance work is carried out when the machine or equipment is out of service.

5. Planned Maintenace

The breakdown of a machine does not occur in a planned manner but maintenance work can be planned well in advance. Planned maintenance is also known as scheduled maintenance it involves the inspection of all plants & equipment, machinery, and building according to a predetermined schedule.

Following is the video lecture on the Role of Plant Maintenance in Production Management