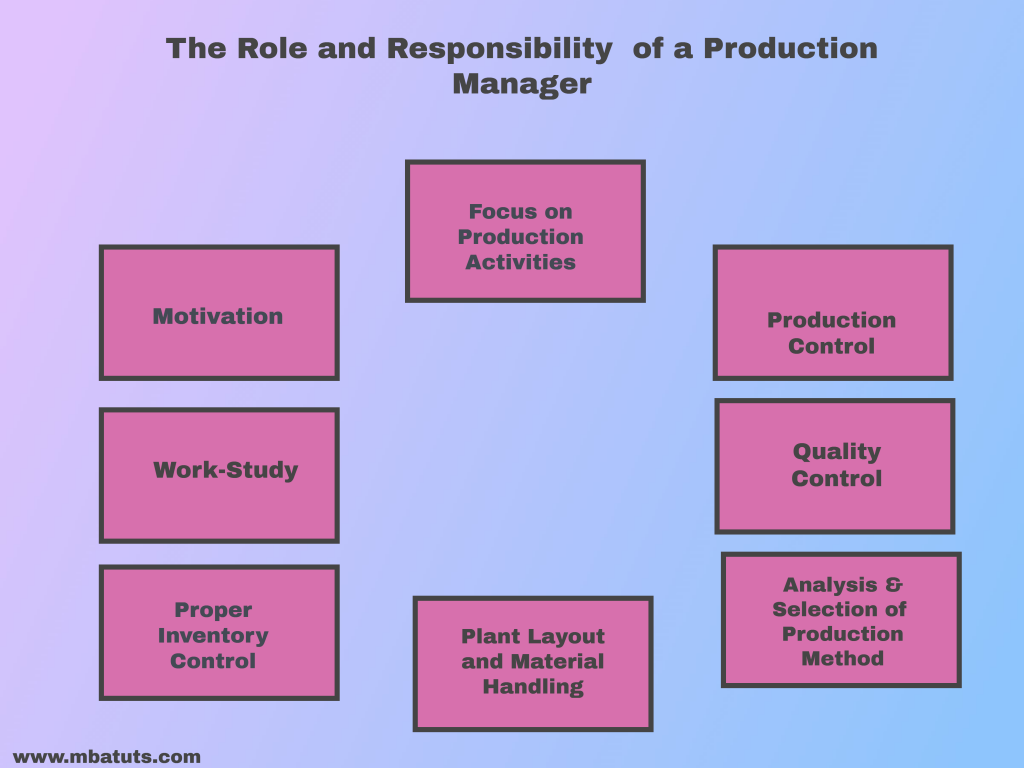

The Role and Responsibility of a Production Manager

As production is a very crucial element in an organization. In the same way, the production manager plays an important role in the workplace.

1. Need to be Focused

In every organization, the Production Manager is responsible for producing the required quantity of the product in time in accordance with the delivery date. The quantity to be produced depends on the demand whereas the time by which the product should be completed is determined by delivering date.

2. Production Control

It is the duty of the production manager to use the resources at his disposal in the best possible manner as well as to regulate the operation in such a way that the desired delivery schedule is maintained. It is been done by routing, scheduling, and inspection during the production process.

3. Quality Control

The major responsibility of the production manager is to manufacture the goods and services within the desired specifications. Though the quality of the finished goods can be ensured by the inspection of finished goods it is better to employ measures, which minimize the likelihood of producing defective items.

4. Analysis & Selection of Production Method

There can be a number of ways in which manufacturing operations can be executed. The production manager should select the most efficient and economical method to perform the operation.

5. Plant Layout and Material Handling

The physical arrangement of manufacturing components and the equipment for handling the material during the production process has a considerable effect on the cost of production. The material handling system and the plant layout should be most efficient for the given situation.

6. Proper Inventory Control

Inventory implies all the materials, parts, supplies, tools, and in-process or finished products kept in stocks for some time. The procurement policy of these items requires careful consideration and analysis. The purchases should be planned in economic lot sizes and the time of purchase should be so scheduled that the investment in the inventory is at the lowest possible level. This implies the determination of economic lot sizes and re-order levels.

7. Work-Study

Work measurement & method study and techniques are applied to find the relationship between the output of goods and services and the input of human and material resources. The production manager should try to find the most appropriate method of performing various operations involved in a particular production process so as to obtain the optimum use of the resource as well as increase productivity.

8. Motivation

Production managers should be able to generate the interest of the workers to increase their efforts by providing them with wage incentives. This will result, in an increase in labor productivity.

Such a great article. This helps me a lot. It’s very informative. And once again thank you so much.